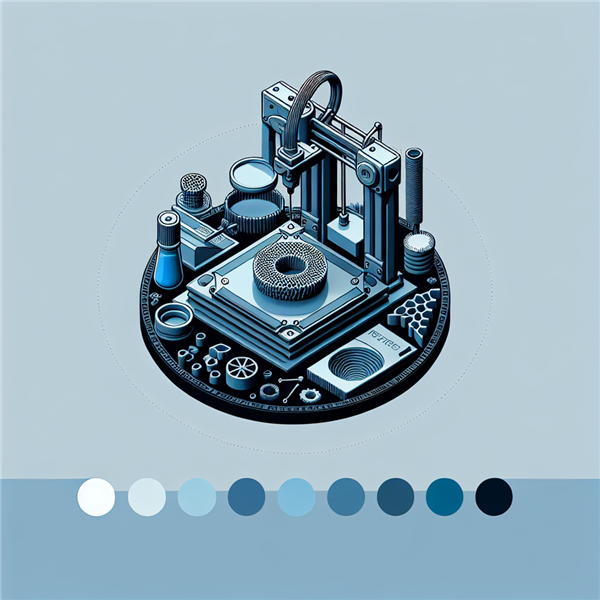

3D Printing Prototyping is the talk of the town in the tech industry, and for good reason. This revolutionary technology has the potential to change the way we manufacture everything from toys to houses. But, what does the future hold for this exciting field? Let’s dive into it.

What is 3D Printing Prototyping?

3D Printing Prototyping is a method of manufacturing where a digital 3D model is transformed into a physical object. This is achieved by laying down many thin layers of material in succession. This method allows for the creation of complex and intricate designs that would be impossible to achieve with traditional manufacturing techniques.

The Current State of 3D Printing Prototyping

In the last decade,

3D printing prototyping has evolved from a niche technique to a mainstream technology. It's used in various industries like aerospace, automotive, healthcare, and consumer goods. According to Statista, the global 3D printing market was valued at approximately $13.78 billion in 2021 and is expected to reach $40.8 billion by 2024.

The Future of 3D Printing Prototyping

Looking into the future,

3D printing prototyping is set to revolutionize manufacturing. Here's how:

- Material Innovation: Future 3D printers will be able to work with a broader range of materials, including metals, ceramics, and even biological materials. This will open up new applications for 3D printing in fields like medicine and construction.

- Speed and Efficiency: 3D printers are becoming faster and more efficient, reducing production times and costs. This will make 3D printing a viable option for mass production.

- Complexity and Customization: 3D printing allows for the creation of highly complex and customized designs. In the future, we can expect to see even more intricate and personalized products created with 3D printing.

Learn 3D Printing Prototyping with Koenig Solutions

Whether you're a professional looking to upskill or a hobbyist interested in the world of 3D printing,

Koenig Solutions, a leading IT training company, offers a comprehensive

3D Printing Prototyping Training Course. This course will equip you with the skills and knowledge needed to master 3D printing prototyping, preparing you for the future of manufacturing.

To learn more about our courses and services, visit

www.koenig-solutions.com.